Between Atoms and Bits

The combination of atoms and bits is the antidote to Ross Douthat's Decadent Society

“There was nothing left that could conquer Rome, but there was also nothing left that could improve it…It was the end of the world, and the worst of it was that it need never end.”

G. K. Chesterton

When Steve Jobs unveiled the iPhone in 2007, he prophesied that it would change the world – it wasn’t an iPod, phone, or an internet communications device, but rather a revolutionary consumer product that would cement the 21st century’s place above all others. Everyone would have the Star Trek computer in their pocket. Surely, the iPhone ushered in a new era; looking back, it might have been the last consumer product to have done so.

Since then, Apple has morphed into a services company, prioritizing product improvements versus inventions. We don’t expect another iPhone; we settle for the iPhone 15 with more cameras and 20 customizable color options. This isn’t relegated to companies, societies fall into this trap when they believe that they’re at the tail end of history.

While we live in the most progressive age, we have to wonder whether western society has become a victim of its own success. Ross Douthat certainly seems to think so. In his Decadent Society, Douthat observes that after the Apollo 11 mission, the peak of human accomplishment, the modern world has been dominated by scelerotic, parochial, and expensive institutions. To be clear, without vision, the dream of an optimistic future fades into the ether.

In response, techno-optimists predictably replied that our cultural ossification is best solved with more software. Still, one cannot help but think that it was this myopic focus on code that veered us astray from the deeper problems in the cultural manifold. Talking about the future now deservedly makes us fearful, not excited. For all their inventiveness, Apple and the other tech giants haven’t been able to save California from apocalyptic fires, much less the violence endorsed by the perfidious leaders of the world’s largest tech metropolis.

All is not lost, however. That the diagnosis lies within Baumol’s cost disease, evil unions or cartels, or even central bank machiavellianism is both over-determined and a non-issue. The response to Douthat’s sclerosis is for society to prioritize expansion over contraction, iteration over repetition, and construction over deconstruction. That can only exist if all of society plays a part; fundamentally, a societal shift around construction cannot just exist in bits (or we’re doomed to repeat the same story of the last 50 years); it must also take place in atoms.

Software has clearly been insufficient – what is required is success in the physical world – the cornucopia of innovation must be a public good. If we need a new vision and engine of growth, manufacturing could be the best place to start. Why? The biggest areas of cost, the ones that disproportionately affect people the most, are in services plagued with an inability to create (construction of homes, healthcare, and education). We need more tinkering in these fields, not less.

Luckily, there is a burgeoning movement around cheaper 3-D printing, materials science, and nanoscale manufacturing that might be as, if not more, revolutionary than the iPhone.

Moving Atoms

The aforementioned problems are, in part, caused by a society focusing on the abstract; it’s lazy analysis to believe all truck drivers will end up becoming programmers. We should remember the tyranny of expertise: those who claim to be experts in a given field, rarely are. But anyone can be involved in the means of creation if the tools are accessible.

In manufacturing, this tool could be 3D printing as a way to turn simple base materials into extravagant pieces of machinery. Of course, these same experts like to say that this idea is a sci-fi dream; in reality, 3D printing has seen runaway growth over the last decade.

Indeed, the sector has nearly reached the tipping point: those with imagination can generate those dreams into imprints. The 3D printing market is expected to grow 24% on average over the next five years, becoming a $35 billion industry by 2025.

When we see such numbers, it’s helpful to consider why this is happening now – why is the time right? What many don’t know is the role of patent protection in curtailing development of 3D printing. Until 2012 and the demise of patents held by HP and GE, original development in this space was difficult – licensing costs were too high for startups. After they expired, suddenly anything was possible and growth, unsurprisingly, blossomed.

But why is this field important? To put it in perspective, manufacturing has a barrier to entry due to the fixed cost of tooling. Companies wouldn’t pay tens of thousands to outfit a factory with tools to build 2 disparate parts – the ability to measurably scale one’s work is important from the outset.

To better understand this, let’s consider the story of Desktop Metal (DM), a company that 3D prints metal and whose cofounder Ely Sachs coined the term “3D printing.” It also holds the record for becoming the fastest company in American history to reach a $1 billion dollar valuation – they did so in a short three years. And, since their launch, they have gone on to use their metal printing technology for over 30 different alloys and hundreds of metal materials.

How it works

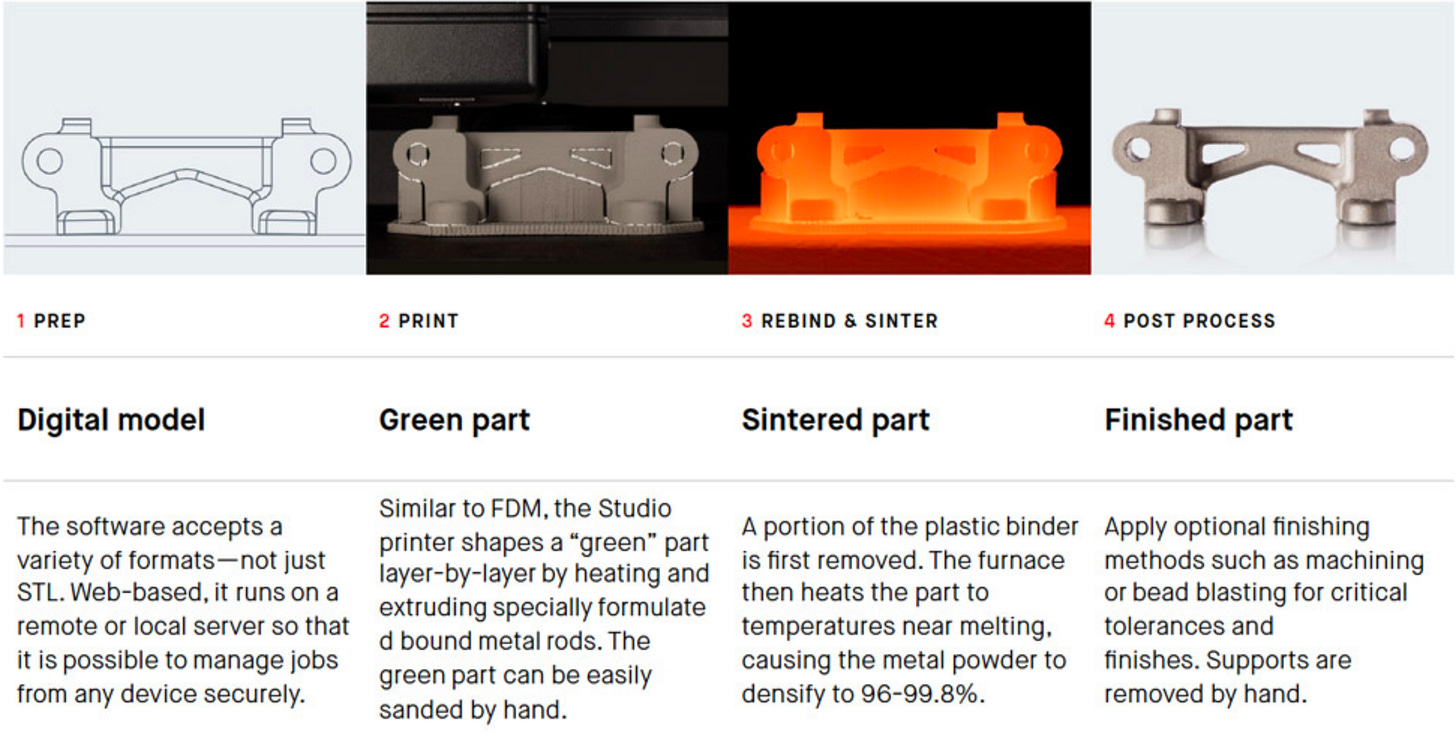

But that isn’t what set Desktop Metal apart. While every other mainstream manufacturer sought a massive technological breakthrough in how factories process their inputs, they adapted their suite of tools to fit existing methodologies like plastic injection molding and sintered metals. By learning from the plastic industry, DM skipped the perfidious parts of manufacturing like loose powder and lasers to generate an aesthetic workflow for the white-collar office. Engineers can design and instantly print metal to production. Simply place a metal cartridge inside the printer, press a button, and what arrives is a hypersleek finished product.

This certainly doesn’t address the full range of the problem nor its complexity. Indeed, sintering – the process of heating an object until its melting point – 3D metal was incredibly expensive and still is. Even now, the market price of a direct metal laser sintering printer (DMLS) can reach $2 million.

However, Desktop Metal managed to create a full-stack process – the studio printer – that sells for around $100k. Critics claim that it’s unsuitable for mass production, but the full production system, of which Ford, BMW, and Caterpillar are customers, can produce more than 10,000 cubic inches daily. In less than a decade, DM’s product system has reduced the cost of 3D manufacturing by more than a magnitude at scale and is over 100 times faster.

And, this is a necessity in rapidly prototyping new types of technology. Volume and cost are the two pillars of modern manufacturing – the aptly named, ‘Manufacturing Hell,’ which Musk coined – and are why Tesla has painstakingly struggled to achieve scale.

So, if there have been notable developments in shaping the tools that create the tools, where do we go from here?

Programmable Matter

First used in 1991, the term ‘programmable matter’ refers to tiny computers that cling together and evolve through nearest-neighbor interactions. The field was inspired by the work of chaos theorists and biologists; they wanted to replicate nature’s non-linearity for computers.

Upon consideration, most of the world operates in a holistic format: everything has second and third order results that interplay with each other. The brain emerges from an assemble of neurons firing in unison; marchings locusts swarm when they meet each other; the shape and behavior of schooling fish and flocking birds drastically differ in groups. For good or bad, emergence acts as leverage and increases the impact of these systems.

The same is true of computing and robotic systems. The subsequent phase of manufacturing will be programming matter for this reason – computers will be able to adapt to external stimuli and continue to evolve without our specified input. In other words, we can interact with information, not in 2d as it lives on a screen, but in 3D where the bits mold atoms dynamically and in real-time.

Claytronics, the study of nanoscale robots capable of self-assembly, will allow anyone to convert an algorithm into an ever-growing physical object. How can they do this? The building blocks are ‘catoms,’ tiny robotic cylinders that cling together with electrostatic interactions. Ships would be able to expand and contract their body to the ocean’s conditions, planes could change the shape of their wings in mid-flight, and our houses would, in fact, look very different as they adapt to environmental conditions over time.

Catoms allow for more degrees of freedom and I suspect that will get around economic barriers like labor costs. One would need to delineate the global maximum, what they want to acheive, subject to cost and time, and the algorithm would take care of the rest. As computing costs drop over time and 'no code’ becomes the de facto standard, the possibilities are immense for how we interact with the world.

Think of all the industries dominated by power-hungry bureaucrats and rent-seeking oligarchs; they thrive on gatekeeping. Earlier, software worked because people could build without permission: building in atoms will require the same approach – the people who can create carefree with a wider assembly of tools.

And for those who think this is an impracticality, we should remember that power is never freely given, it's taken through either a change in philosophy or the wielding of the sword. Allow the former and we perhaps we may never see the latter.

Newton once famously proclaimed that “if others would think as hard as I did, then they would get similar results.” This takes us back full-circle – computers may follow our wishes, but we have to think long and hard about the most important problems of our time. The ongoing culture wars, first beginning in the 1960s, played a leading role in this technological stagnation – solving that may be how we return to the 1950’s idea of the 21st century as Douthat describes. Allowing others to taste and reap the rewards of technology in both atoms and bits, despite their backgrounds, could be the way out.

And, if we accept the inevitable, the singularity or the biblical apocalypse, why bother to think of decades yet to come? Will manufacturing solve the underlying issues that led us into these troubled waters? Perhaps not, but I believe that the future is malleable and subject to our actions: the antecedents to the culture wars will disperse if we resoutely right the western world’s trajectory toward the axis of positive-sum growth. For a stagnant world, abound with decadence, is not much of a world at all, it’s merely going gently into the good night.

Note: I wrote another piece last week with Conversion Capital, The Republic of Big Technology.

Until next time,

Anirudh

Fascinating! 'Programmable matter' fits right into Michael Nielsen's speculations on the 'varieties of material existence': http://cognitivemedium.com/vme